Acquisition of Winning BLW

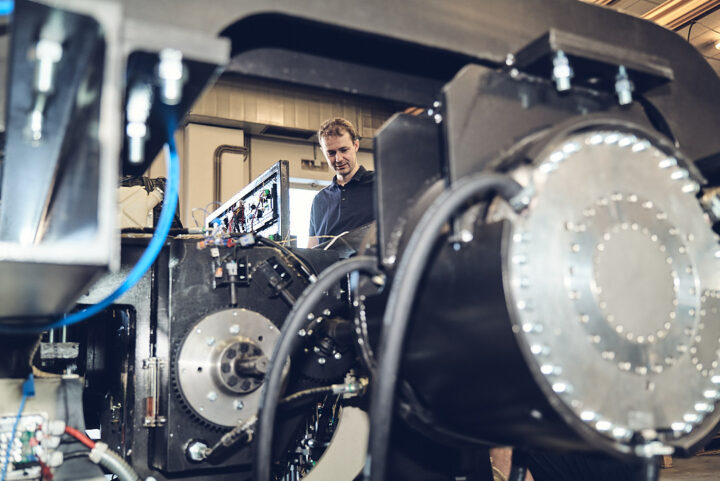

By entering the automotive segment, we have expanded our activities on a level which we believe has not only economic, but also environmental potential. Nowadays, the development trend is set mostly by electromobility and so through Winning BLW we can help to determine the future. We now supply more than 10% of our products for electric cars and we are constantly developing new technologies.

Our entry into the automotive segment broadened our activities into a dimension in which we expect not only economic, but also environmental potential. Electro-mobility determines the direction of all current development, and Winning BLW allows us to put our imprint on the future. Already over 10% of our current products are designated for electric cars, and we are constantly developing new technologies.

We have taken an active leadership role and strengthened management with the addition of a key figure, Christopher Guhe. With his many years of experience in the field, he brings a fresh outlook and modern management style with minimized centralization of responsibilities, and also an open door to shareholder dialogue. We also rejuvenated the cadre of top engineers and were able to save most jobs.

The three Winning BLW production facilities in Duisburg, Munich and Remscheid generate more than €200 million in annual turnover and employ over 1000 people.

This focus upon strengthening the foundations gave rise to our joint venture with EP Industries, a.s., thus forming Winning Automotive a.s. This allows us to continue our development in the automotive sector through new acquisitions in related industries, Winning Group’s prospects notwithstanding. “I am sure that together we will become a leader in the European market in the upcoming years,” says Sebastian P. Wagner, CEO and chairman of the board of Winning Group a.s.